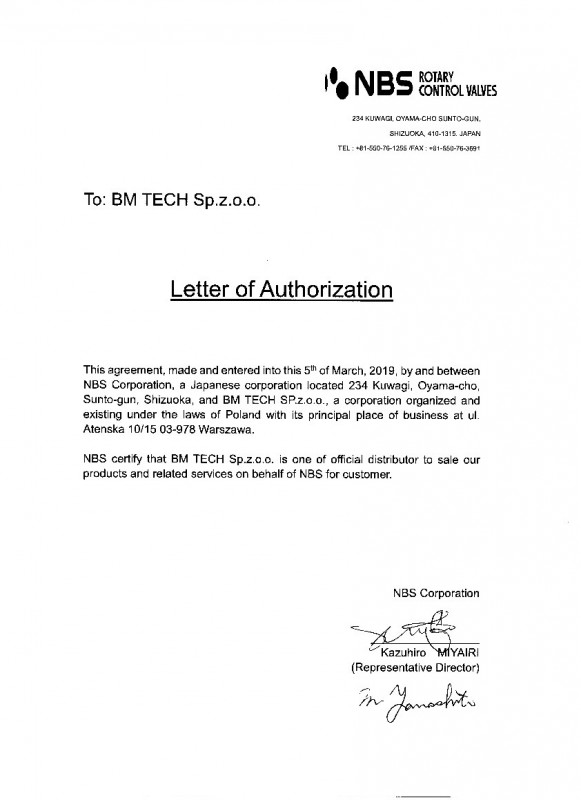

BM TECH sp. z o. o. is European Authorized Representative of the Japanese manufacturer of Rotary Control Valves and Actuators - NBS CORPORATION based in Kuwagi, Oyama-cho.

NBS CORPORATION is a global supplier in the field of control and shut-off valves as well as industrial automation.

It produces valves and actuators for industries such as:

As part of our offer, we provide the following NBS products:

1. Conrol valves:

2. Automated ON-OFF valves:

3. Throttling valves:

• Pneumatic actuators–– UNIPOWER NC / NE series, UNIPOWER NS series.

• Manual gears – RGM mmodel.

4. Nominal pressures for valves

• PN 10, 16, 25, 40.

• ANSI Class 150, 300.

5. The production process:

The proper selection of materials allow the use of NBS UNICON / UNIFLOW valves to work in cryogenic systems (-196 ℃) and in high-temperature systems (+450 ℃).

The patented ANTI-VIBRATION system ensures longer valve durability, extended technical parameters and higher utility value.

NBS UNIFLOW / UNICON is a high-performance valve with double eccentric disc design, meeting all requirements for on / off valves and control valves. The valve provides long-term leak tight shut-off, excellent flow characteristics and long service life. The design of the valve ensures no movement between the disc and the valve sealing system, which facilitates complete tightness. A perfectly designed and fixed gasket with a clamping ring does not have any additional loads apart from the sealing function itself.

NBS UNIFLOW / UNICON valves are offered with adapted double-acting UNIPOWER NC / NE or NS actuators (actuators). Type NE and NS-00NS are spring return actuators. The selection of the actuator depends on the valve diameter, the type of gland packing and its use in the installation. It should be noted that the above-mentioned actuators are drives that quickly - open or quickly - close the valve, and their use allows you to control the valve opening / closing process for up to 1 second. By means of two independent adjustable screws, it is possible to set the end position in the area of - 3 ° + 3 °. The advantage of this solution is the control of the closing / pressing force of the damper disc to seal only until it is tightly closed, but no further. It ensures perfect valve tightness and significantly extends the replacement period of the gasket, which reduces repair costs and installation downtime.

A specially designed handle and coupling connecting the actuator with the valve facilitates the axial assembly of the assembly on the installation. This has a significant impact on the longer service life of the unit, its smooth operation and shorter downtime periods of the installation.

NBS UNIFLOW / UNICON valves are specially designed for oxygen service in a wide range of applications including both on-off operation and proportional control. When manufacturing a valve, there is a rigid procedure for the preparation of components, assembly, testing and packaging of the valves. The purpose of this is to ensure cleanliness and to prevent oxygen from reacting with grease, oil and other foreign substances inside. The chemical treatment of parts and components (OXYGEN SERVICE) procedure is implemented to maintain oxygen purity - "Free of oil and grease for oxygen service", purity oxygen, free of oil and grease for oxygen service.

6. SPARE PARTS AVAILABLE.

Most of the spare parts for NBS UNIFLOW / UNICON valves and UNIPOWER actuators are available in our warehouse.

BM TECH stocks kept for the needs of our customers concern several copies of repair kits for individual sizes of valves and actuator sizes.

Permanent cooperation of BM TECH sp.z o.o. with NBS Corporation enables you to get spare parts much faster at very competitive prices.

If it is necessary to repair a larger number of valves / actuators, our company is able to deliver them to you within 7 working days from the date of placing the order.

In connection with our cooperation with NBS Corporation, our company has a service team trained in Japan that performs repairs / overhauls of devices "in situ" or in our workshop.

7. REPAIR AND MODERNIZATION OF NBS UNIFLOW / UNICON VALVES AND UNIPOWER ACTUATORS

Company BM TECH sp.z o.o. has the appropriate competences and an experienced team of service technicians, providing repair and replacement services for individual components worn in the valve and actuator life cycle. We start our work with a technical audit of the valve and actuator (diagnostics in the process of disassembly of components), consisting in measuring the sensitive dimensions of individual parts and relating them to the factory dimensions. This allows you to minimize service costs and define time intervals for new inspections and their scope (Condition Based Maintenance). The user of NBS products is able to plan the necessary inspection and reduce the time needed for its implementation, and thus eliminate or minimize the time of technical downtime of a given installation.

Regular servicing of the valve and actuator significantly extends its lifetime and failure-free operation. The benefits that result for you from such an approach are for us not only satisfaction, but also a diligent duty in our daily work. The report you receive from the valve and actuator service includes information related to the replacement / repair of individual components and the approximate date of the next service and its technical scope. Our database and after-service labeling of the valve and actuator will help you decide "what and when we need to do, repair, replace" - the so-called predictive maintenance ((Predictive Maintenance). This will allow the User to properly plan the repair budget and reduce it to a minimum. As one of the few companies we have and maintain high inventory levels, and our response time to your needs (failures) and valve or actuator repair time have been shortened Thanks to this approach, you are able to define the optimal moments for the implementation of technical services.

By maintaining devices and systems in the above manner, it is possible to achieve longer service life and reduce the total cost of maintaining the installation. At the same time, it allows to significantly reduce the risk of damage or failure of a given device.

We not only offer you access to spare parts for NBS Corporation valves and actuators, but we also provide services in the field of technical consultations, technical audit as well as repair and modernization works. We will make it easier for you to find the causes of repeated failures and eliminate them from the production cycle.

We provide maintenance services related to the general overhaul of the valve and actuator, bringing it, in fact, to the factory condition. Our prices are very competitive and the service of the device has a 6-month warranty.

8. SALE OF NBS VALVES AND ACTUATORS

We also invite you to purchase new devices from NBS Corporation. Our company with extensive experience in the selection of valves, actuators and necessary accessories will help you choose the right set that meets the most stringent technical requirements and is characterized by excellent Japanese quality. This will ensure trouble-free operation of the valve and / or actuator for many years. We send product catalogs in both pdf and paper format at your request.